UNITED FOR YOUR SUCCESS

In the machine industry, long-term customer relationships are the foundation for shared success, with manufacturers and customers maintaining steady contact over many years. But what distinguishes these relationships? How can mutual appreciation be achieved? To commemorate the 30th anniversary of the UNITED GRINDING Group, “Motion” posed these questions to an international selection of customers

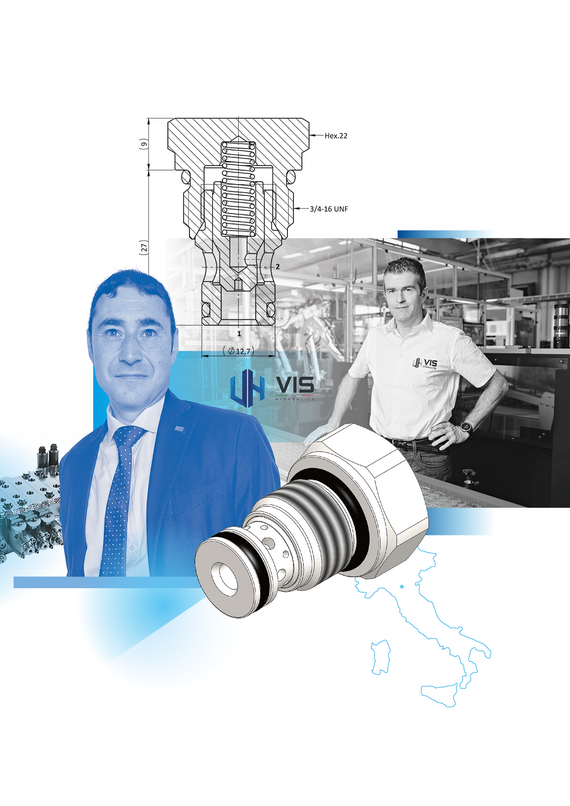

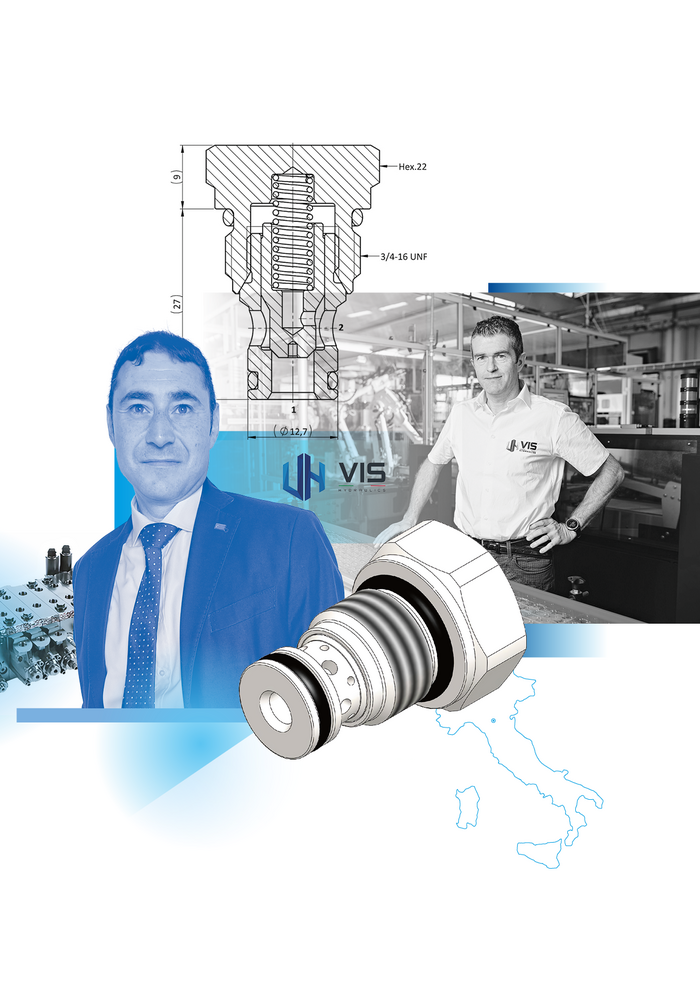

“When you go home to your family in the evening,” asks Adamo Venturelli, CEO VIS Hydraulics, near Bologna, “What do you talk about around the dinner table? You talk about the people you met and the things you experienced with them.” Italy’s Venturelli is another long-standing UNITED GRINDING customer we surveyed for this article. This time the discussion focused less on technical topics and more on the interpersonal relationships that allow businesses to work together successfully in the first place. “It doesn’t matter if you have the best technology if the people who are supposed to work with it don’t understand each other,” Venturelli concludes. “It’s a people business,” he says, “at least that’s how we at VIS see it—and as far as I can tell, the colleagues at STUDER see things the same way.”

PROXIMITY, TRUST, RELIABILITY

You might think that Italians living in their warm Mediterranean climate are more inclined to personal warmth than Swedes in the cold north or the Japanese with their cool reserve, but after talking with customers in different countries and their contacts at the brand companies of the UNITED GRINDING Group, we have to question these old stereotypes. In all five of the examples, our interviews revealed just how much the success of any business collaboration depends on the ability of the people involved to connect on a personal level. In principle, everyone agreed that customer/supplier relationships are built on very similar foundations to relationships in the private sphere: proximity, trust, reliability, and shared values.

Global relationships

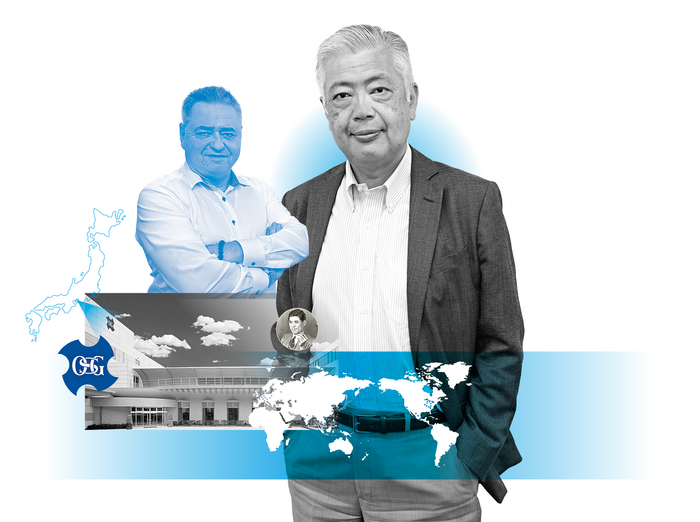

OSG and WALTER have much in common: a global orientation—and commitment to high standards and innovation

Takeo Koji is the Managing Executive Director of OSG Corporation, a leading player in the international machine tool industry. Founded in 1938, OSG operates with over 7,000 employees in 33 countries, manufacturing and selling cutting tools such as taps, drills, and end mills worldwide, and are the world’s largest manufacturer of solid tools. Takeo’s experience with WALTER EWAG goes beyond just years of working together; he also personally visited Tübingen, Germany, in the 1980s: “My first impression back then was: WALTER is similar to OSG. At least in view of the fact that both were owner-operated companies at the time. And even back then WALTER was famous for high-end machines and value-adding equipment.” Today, there are three main reasons why OSG likes to work with WALTER: “Firstly, reliability. Secondly, consistency. And thirdly, its conservative approach.”

CLEAR WORDS

The video interview, which Takeo conducts from a conference room at OSG headquarters in Toyokawa (Aichi Prefecture), is also joined by Yasuhiro Tomida and Jun Ikeda from WALTER EWAG Japan, as well as Michael Schmid, who is responsible for all WALTER EWAG business in the Asia-Pacific region. Schmid, however, is not at OSG headquarters, but links in from a conference room at a trade show in Bangkok.

Takeo remains focused on every moment of the conversation and proves a man of clear, concise words. “There’s an important reason why we work together—OSG is active globally, and we have production facilities around the world. And WALTER supports OSG with this.” Michael Schmid adds: “Our partnership is very extensive. We’re both concerned with customer support. We work closely with OSG maintenance staff. Our application engineers talk back and forth a great deal regarding application and production topics. We meet regularly. We have relationships with OSG at all levels, and that also helps solve problems.”

Pictured: Adamo Venturelli, CEO VIS (right), Diego Capitanio, STUDER (left)—a friendly pair

Quality knows no compromise

VIS and STUDER see fully open and direct communication as the basis for their shared success—and the passion for great machines

“When the customers come to visit our company and see all the beautiful STUDER machines, they say: ’Oh, you use STUDER—but aren’t those the most expensive machines?’ And I say yes, but they’re also the best. If you want the best car in the world, where do you look? If you’re looking for performance, warranty, durability, then it’s Ferrari—they’re the best but also the most expensive. And at that point it’s clear what you need to do.”

Adamo Venturelli never shies away from new comparisons when he praises his STUDER machines. He is CEO of VIS, a hydraulics and valve manufacturer he founded in 2009 with his brother Davide. The two were encouraged by the successes of their father, whose “Tarp” developed from a small turning shop into an industrial giant.

During the interview, in which STUDER Area Sales Manager Diego Capitanio also took part, Venturelli is in a great mood as he recounts his firm’s beginnings:

“Our partnership with STUDER goes back to the era of my father’s company, 20 years ago. That’s when we bought our first S25, as well as a series of other STUDER machines. When VIS Hydraulics was founded in 2009, we had to choose a partner for our cylindrical grinding machines. It was the year of the Lehmann crash—a time of deep, global crisis. It was brave but also a bit crazy to start a company in that hurricane. We spent much time pondering this or that, and we also looked at other companies. But in the end, we saw from our father’s experience that there can be no doubt that STUDER is the right partner.”

ENTHUSIASM AS A USP

Today VIS has 18 STUDER machines in use; five STUDER S11s, all with loaders, were only delivered in 2021—and VIS has been internationally recognized for some time as a key supplier of hydraulic valves and components, including for example in agriculture. With the option of high-speed grinding, the S11 offers opportunities for further efficiency gains on the market. “The S11 is one of the most interesting machines we have,” says Venturelli. “It is of very high value for our company because efficiency is the key factor in guaranteeing our success on the market.”

So what drives this successful partnership? “We have totally open and direct communication with the STUDER world. Diego is our primary contact, and his technical knowledge holds enormous value for us. He doesn’t just sell machines from the catalog. This makes it much easier to talk to him. He is simply not a typical salesperson.” Diego Capitanio for his part says: “Sure, it’s wonderful to hear all these nice words here. But when you’re talking about reasons for success, then you have to mention enthusiasm. It’s what the VIS brand stands for, and Adamo is the right person to represent this value.”

A FIRE THREATENS EVERYTHING

When a fire broke out one Sunday in September 2021 at one of the VIS plants in Pavullo nel Frignano, several machines were affected by the fire, some others destroyed. A team of VIS and STUDER employees was soon working day and night and was able to restore full two-shift operation just four weeks later—sparing the end customers virtually any inconvenience. “This wasn’t just about the business relationship, instead it was about surviving an ordeal hand in hand with a true partner,” remembers Venturelli. “It was a unique experience that allowed the relationship to grow even further.”

Two companies, one language

Seco and EWAG are united by the joy of customized, customer-oriented solutions—and something you might even call friendship

Central Sweden, in the historic Bergsladen mining area. The small municipality serves not only as the headquarters for Seco Tools, but it is also known as the birthplace of the Swedish steel industry. Seco is deeply rooted in Swedish industrial history. It all began in 1873 when Fagersta Bruks AB was founded in Fagersta, Sweden. Steel wire and steel tubes, rifle barrels, and springs for rail vehicles were manufactured here in the Bergslagen region. In 1932, the company started small-scale production of a carbide product called “Seco.” Seco is Latin for “I cut.”

Today, Seco has 4,100 employees and is represented in 75 countries, with machining solutions for milling, turning, drilling, and tool holding fixtures for the aerospace, automotive, medical technology, power generation, and utility industries. After the dismantling of the steel industry in the 1980s, many plants in Fagersta are now considered shrines of industrial history, and the Engelsberg smelter’s plant has been named a World Heritage Site.

HOW DO YOU PLAY ICE HOCKEY?

And how do the locals here play ice hockey? This is an important topic in the interview with Andreas Westman, Manufacturing Engineer Grinding, and Georg Schröer, Head of Service at EWAG. To resolve this issue, we have to look back to December 1990, when Schröer “Jojji” was asked to suit up for the Seco-Ludvika team against the team of Motherhouse Seco-Fagesta at its annual ice hockey match at the Ludvika site … the Seco team was down a man. Asking Schröer to fill in was only natural, since he was clearly already seen as being part of the Seco team. “I’m not bad at ice hockey,” recalls Schröer. “But shortly after the match began, I asked myself: ’Why can’t I get a good lick in on these boys?’ It was hopeless. After the match we went to the sauna—and then I learned that some of them played for the national team of bandy.

And that’s not all: They had different skates, capable of gliding much farther than normal ice hockey skates. They take two strides with them, and they’re already five meters ahead. But they only told me that after the game.” Westman laughs as he hears the story, the story about the higher speed which can be achieved by longer gliding surfaces of the runners he can only confirm, since he plays bandy himself.

SPONTANEOUS, TRUSTWORTHY COMMUNICATION

At that time, in 1990, Georg Schröer was still quite new to Seco. He got to know the company in 1988 when Jan-Olof Lundequist, the predecessor to Andreas Westman, ordered the first RS-12-CNC, followed by machines from the Ewamatic, Ewamatic Line, Compact Line, and Ewamatic Linear. At the time, Schröer had moved to Sweden and then back to Switzerland in 1999, where he has been looking after Seco ever since. He hasn’t forgotten his Swedish. “The good thing is that you can speak Swedish, which makes it easier for us,” Westman says. “English would be a foreign language for both of us.”

Trusting, spontaneous communication is the basis for collaboration—and a cultural commonality: “Like Seco, EWAG is essentially a family business, which is also one of the reasons why we get along so well,” says Westman. “We think about the customers, not just one-size-fits-all industrial solutions. And EWAG is also service-oriented and highly individual. There isn’t one standard machine, but rather a base that is then always adapted for our products so that a good solution is always found.”

Schröer has an example ready for this: “Seco has a lot of custom products that require development and special handling. This was recently the case with a drill tip, for which we had to create a completely new handling setup to automate everything and eliminate the need for someone to stand next to the machine the whole time. The solution was image processing combined with robotics.”

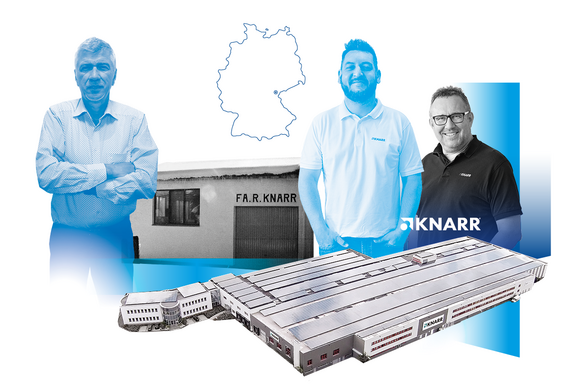

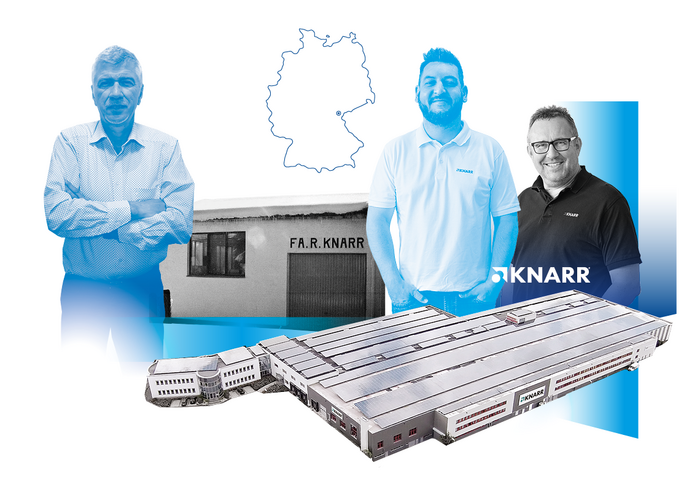

industrial district—with photovoltaics on the roof since 2009. Pictured, right: Alfred Weber, Thomas Wunsiedler, KNARR, Ralf Traber, BLOHM JUNG

Growing together through success

KNARR and BLOHM JUNG have grown together. Over almost 30 years, from the first machine to the 31st as it stands today

The proverbial story of companies being founded in a garage is cliche—but it holds true at least here at Orter Strasse 15 in the Wüstensel district of the small Bavarian town of Helmbrecht. As explained in an interview with Thomas Wunsiedler, Deputy Head of Marketing and Sales Representative, the firm’s history traces back to 1994: “There was a small, old weaving mill with a larger entrance that young toolmaker Alfred Knarr chose to rent. One of the first machines he purchased for this space was a JUNG HF 50, a flat grinding machine, year of manufacture 1980. The grinder was added later, and it’s still on the premises today.” The JUNG HF 50 is actually still in use today as well. Meanwhile it is one of 31 machines from the UNITED GRINDING Group: two MÄGERLE, four STUDER, and 25 BLOHM JUNG machines.

Founded in 1994, KNARR is almost the same age as the UNITED GRINDING Group, which was founded in 1993. “Here at KNARR, we started with three employees alongside the boss. We now count 250 and are heading towards 280. We have grown together with UNITED GRINDING, I think it’s fair to say.”

Just how well the companies are in sync is immediately noticeable in the interview, which included Alfred Weber, Deputy Production Manager and QMO at KNARR, Ralf Traber, and Siegfried Völkel in addition to Wunsiedler. Traber is the Sales Manager at BLOHM JUNG, and Völkel represents the sales company Berner + Straller, which has supported the partnership since the very start.

In Völkel’s words: “I remember driving to JUNG in Göppingen after an AMB trade fair in Stuttgart, late in the evening because Mr. Knarr wanted a ’J630’, and we knew there was one there. It was pitch dark, and we had to look for the light switches.” Weber says: “The machine wasn’t even ready. I think the issue was how the digital display should be implemented on the machine. Mr. Knarr wanted to know how far things had progressed. He knows everything about the machines inside and out. That’s why he’s always there when it comes to larger purchases. He knows what he’s talking about.” Traber adds: “Mr. Knarr is an original. A guy. But in a good way! If a young man, as Mr. Knarr was at the time, hopes to set up his own company, then he needs the right mindset. The focus needs to be on moving forward …” Völkel adds: “ … and of course also: short decision-making paths. A typical German medium-sized company.”

A savior on five axes

Hanza and MÄGERLE support large customers from the gas turbine industry—with a great deal of trust in the partner and the latest technology

Ola Svensson, Site Manager at Hanza, is cheery as he joins the video interview, greeting the other participants with a “Morning, Morning, Morning, and Hi Stefan” to Stefan Zürcher, Head of Sales and Marketing at MÄGERLE and the “Motion” editor. Hanza has offered complete solutions in advanced machining for turbine, aviation, industry, and offshore since the 1970s and serves customers from the gas turbine industry such as Siemens or Energy Sweden in six production clusters.

“In 1995, Hanza made the big switch to the turbine business,” says Svensson, “we initially worked on three-axis MÄGERLE machines and a BLOHM double-wheel machine.” When prices for turbines began to fall, it was time to become more efficient. “Roger Persson and I visited MÄGERLE and initially considered purchasing another three-axis machine in order to grind the turbine blades. But then they showed us a completely new machine — and we had a lot to talk about for the next few days.”

The new machine was the MFP 50 — the first with five axes. “Hanza was one of the first companies to embrace MÄGERLE five-axis technology,” says Stefan Zürcher. “And because Hanza itself was still relatively new to the turbine business, it was possible to produce more efficiently from the outset. They were pioneers.” “After a year that featured a lot of help from MÄGERLE, we were able to reduce the number of setups for gas turbine parts for Siemens from the previous six or seven to two,” Svensson reports. “This was the prerequisite for remaining on the market at all, because prices had fallen further in the meantime.” Here too, trust and communication were key to success: “We know each other very well, and we know exactly what the other needs. When we sit down to talk, we can go to the point immediately. And of course we also benefit from the experience MÄGERLE has worldwide. But we don’t do everything that MÄGERLE says — and MÄGERLE doesn’t do everything we say. And that’s the way it should be.”